Introduction to Calipers and Their Importance in Engineering

Calipers are precision measuring instruments widely utilized in various engineering disciplines for accurate measurement of dimensions. These tools are designed to gauge the distance between two opposite sides of an object, making them vital in both industrial and laboratory settings. There are several types of calipers, including digital calipers, vernier calipers, and dial calipers, each offering unique features that cater to different measurement needs and preferences. The working principle of calipers involves the use of two arms, one fixed and the other movable, which can be adjusted to span the object being measured. This simple yet effective mechanism allows for the assessment of internal and external dimensions as well as depths.

The importance of accuracy in measurement cannot be overstated in engineering applications. Every engineering project, whether involving the manufacturing of components or the assembly of intricate systems, relies on precise dimensions to ensure proper fit and functionality. Calipers play a crucial role in maintaining quality control by allowing engineers to verify that parts meet specified tolerances. This ensures consistency in production processes and minimizes waste caused by faulty measurements.

Furthermore, calipers not only support the design phase through accurate prototyping but also assist in the final inspections of completed products. As an essential tool in engineering, calipers contribute significantly to enhancing the quality of designs and ensuring compliance with industry standards. By investing in quality calipers, engineers can achieve more reliable outcomes, reduce the risk of errors, and ultimately enhance the effectiveness of their projects. In conclusion, understanding the workings and applications of calipers is essential for any professional in the engineering field, as they are indispensable in the pursuit of precision and accuracy.

Types of Calipers Used in Engineering

Calipers are essential measurement tools in engineering, used for precise measurement of dimensions such as diameter, depth, and thickness. Various types of calipers serve specific purposes, each with distinct features and applications.

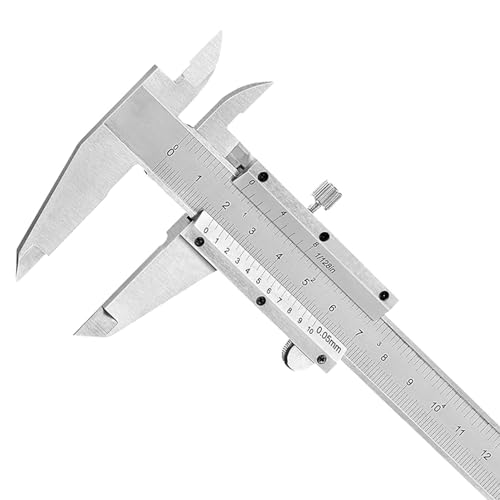

Vernier Calipers are among the most traditional measurement tools. They consist of a main scale and a sliding vernier scale that provides readings with greater accuracy than a standard ruler. Vernier calipers are especially effective for internal, external, and depth measurement. Their accuracy, often up to 0.02 mm, makes them suitable for precision tasks in mechanical engineering. However, the need for skilled handling and manual reading can introduce human error.

Digital Calipers have largely replaced conventional calipers in many engineering environments due to their ease of use and enhanced accuracy. They feature an electronic display that provides direct readings of measurements, often with a precision of 0.01 mm. Most digital calipers also allow users to switch between metric and imperial units easily. While they eliminate reading errors associated with manual scale interpretation, they are dependent on battery life and may not withstand harsh environmental conditions.

Dial Calipers, akin to vernier calipers, display measurements via a dial gauge. They are traditionally favored for their analog display, which some engineers find easier to read than digital displays. The typical resolution of dial calipers is 0.01 mm, bridging the gap between analog and digital measurement devices. However, similar to vernier calipers, they still rely on manual reading, which may pose challenges in precision applications.

Lastly, Micrometers are specialized calipers designed for measuring small distances with extreme accuracy, often within the range of 0.001 mm. Their structure includes a calibrated screw mechanism, allowing for fine measurement of the thickness or diameter of materials. While they offer unparalleled accuracy, micrometers are less versatile than calipers, as they primarily measure external dimensions and lack depth measuring capabilities.

Each type of caliper has its unique features, advantages, and limitations, making it crucial for engineers to select the correct tool based on the specific measurement requirements of their projects.

Applications of Calipers in Engineering

Calipers are fundamental tools that find extensive applications across various branches of engineering, including mechanical, civil, and electrical engineering. Their primary function is to measure the dimensions of objects with great accuracy, making them indispensable in the manufacturing and quality assurance processes.

In mechanical engineering, calipers are used to ensure that components meet precise specifications. For instance, in the fabrication of machine parts, calipers help engineers measure the thickness, diameter, and length of various components. This ensures that parts fit together correctly, which is crucial for the functionality of machinery. In addition, they facilitate the verification of tolerances, which are the permissible limits of variation in a physical dimension. Regular checks using calipers minimize the risk of component failure due to incorrect dimensions.

Civil engineering also heavily relies on calipers. During the construction of structures such as bridges and buildings, engineers can measure the dimensions of concrete forms and steel reinforcements. This measurement is vital to ensure structural integrity and compliance with design specifications. Moreover, they are used in site surveys to establish the dimensions of land parcels, aiding in proper planning and resource allocation.

In electrical engineering, calipers assist in measuring the dimensions of circuit board components or wire gauges. Accurate measurements are essential in creating efficient layouts, ensuring that components can be assembled without obstruction and that they function properly within the given design parameters. An example of their application can be seen in the production of printed circuit boards (PCBs), where calipers are used to verify the dimensions of traces and pads.

Overall, calipers serve critical functions in achieving precise measurements that are essential for the successful implementation of engineering projects across various disciplines.

Best Practices for Using Calipers Effectively

Calipers are vital tools in engineering and manufacturing, enabling precise measurements that are critical for quality control and product design. To maximize the effectiveness of calipers, one must implement several best practices that underscore the importance of accuracy and tool longevity.

Firstly, proper handling of calipers is crucial. Before taking measurements, always ensure that the calipers are clean and free from any debris or contaminants. It is advisable to use a lint-free cloth to wipe down the measuring surfaces. Additionally, be mindful of your grip on the calipers; holding them firmly but gently helps prevent any undue pressure that might lead to measurement errors.

Secondly, when taking measurements, it is important to position the calipers correctly. For external measurements, grip the object firmly and allow the calipers to close until they gently touch the subject without excessive force. For internal measurements, ensure that the caliper’s inner jaws are placed evenly inside the object. Always take measurements at the same point on the item to ensure consistency and repeatability.

Another key aspect of using calipers effectively is calibration. Regularly calibrating calipers can prevent measurement discrepancies. It is advisable to check the calibration before significant measurements are taken and after any alteration to the tool. This ensures that measurements remain accurate and reliable.

Avoid common mistakes such as reading the measurement improperly or failing to align the caliper correctly. Always take care to view the scale from eye level to minimize parallax errors. It is also recommended to take multiple readings and average them out to obtain a more precise measurement.

By adhering to these best practices, engineers and technicians can enhance the accuracy and durability of their caliper measurements, facilitating better outcomes in their projects.